Kitagawa, which proposes the future of manufacturing,

shows the next-generation technologies online.

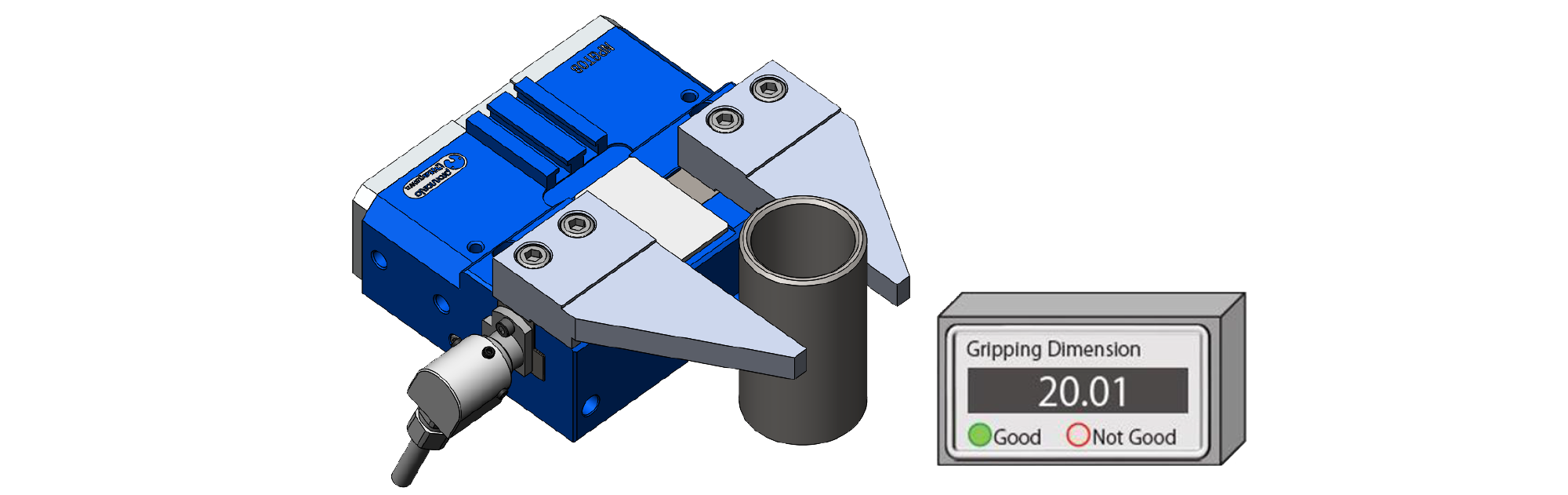

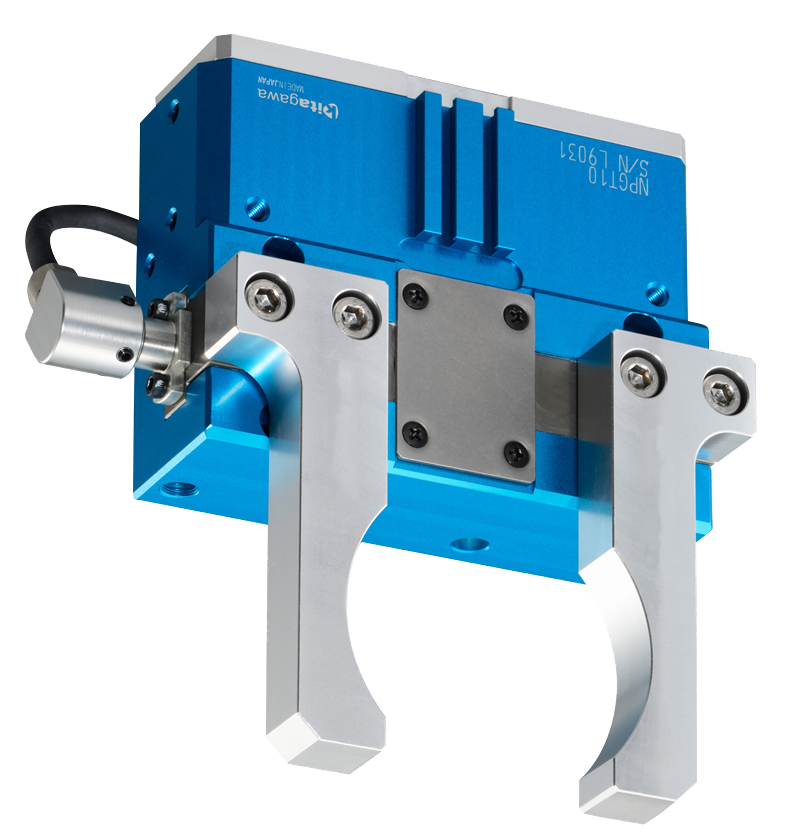

2-jaw parallel gripper with measuring function NPGT_S series

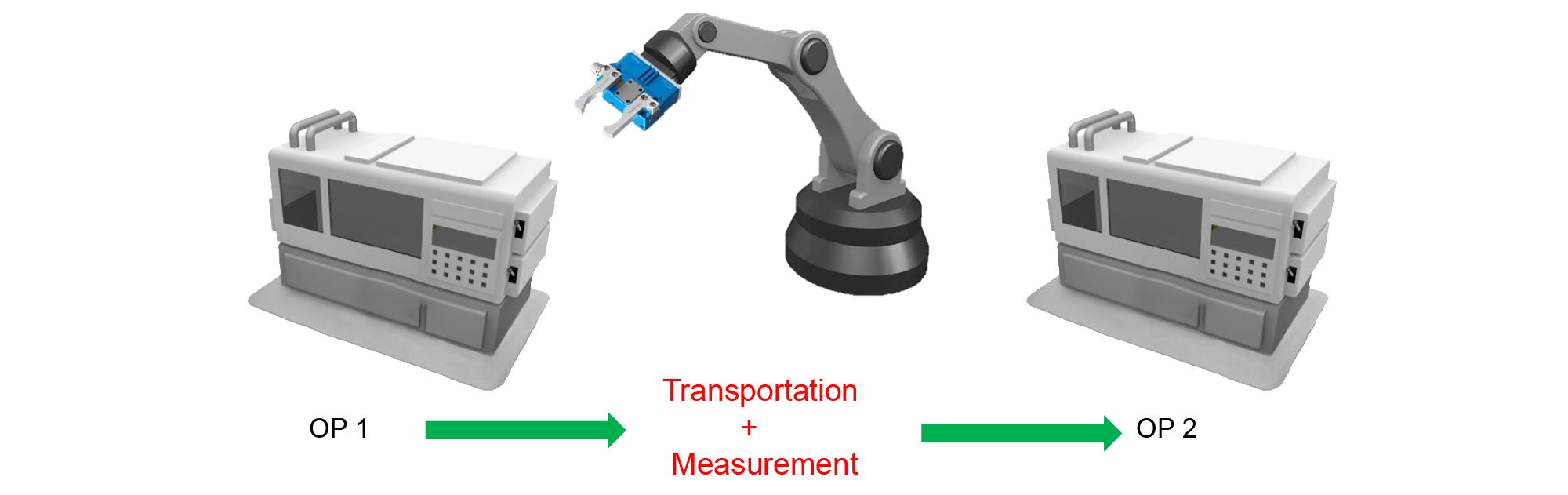

Check dimensions while transporting

Possible to measure the dimension of where the gripper grips by the built-in measurement scale.

It realizes the competitive production line through automation, labor saving and productivity improvement.

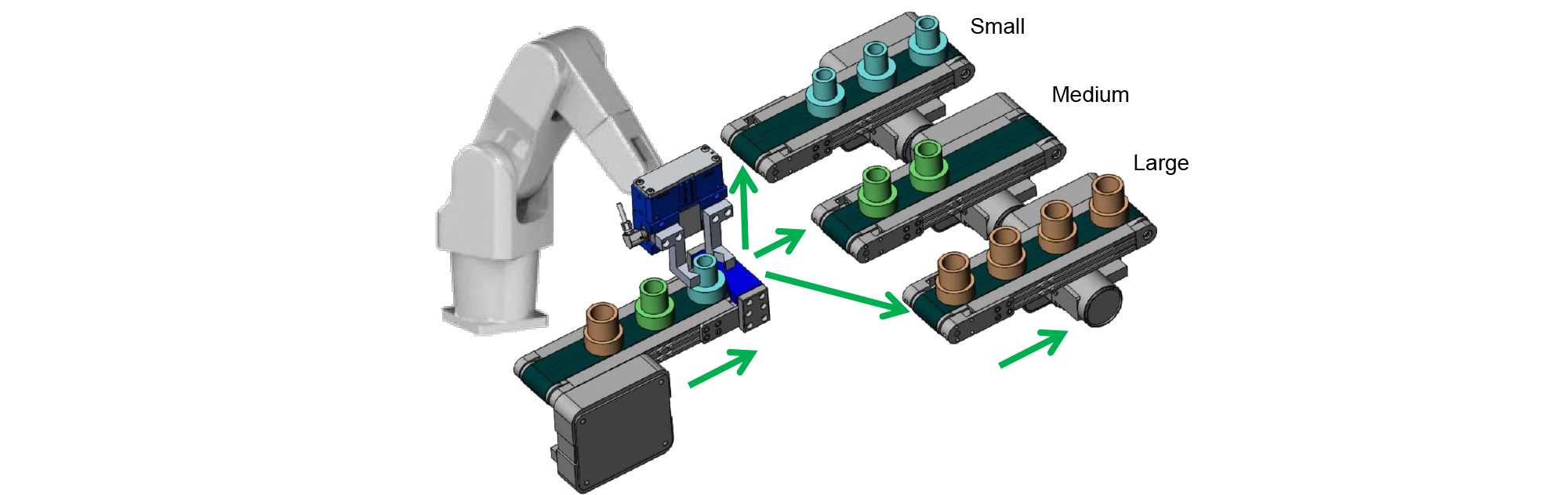

Check dimensions while transporting

Possible to measure the dimension of where the gripper grips by the built-in measurement scale.

It realizes the competitive production line through automation, labor saving and productivity improvement.