Kitagawa, which proposes the future of manufacturing,

shows the next-generation technologies online.

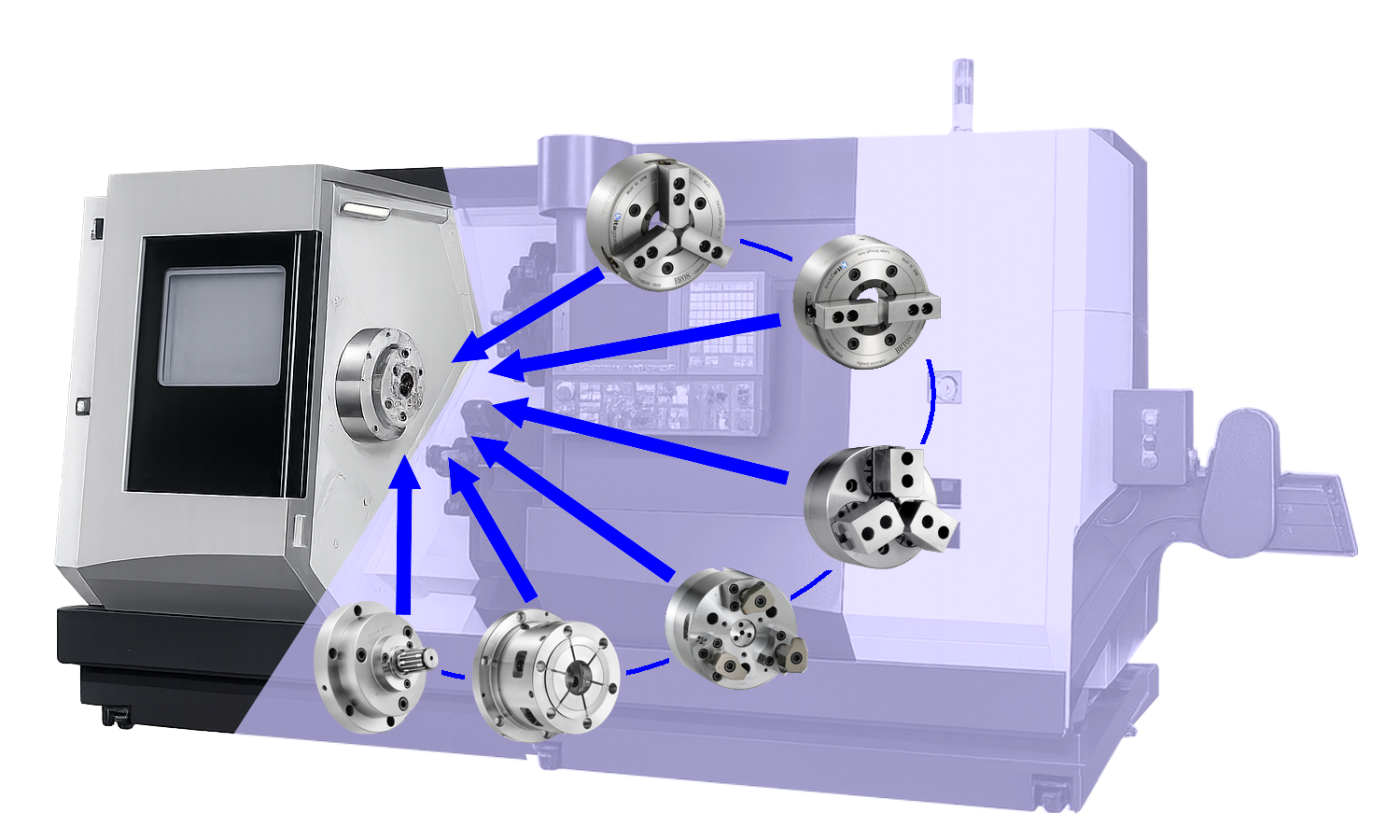

Ultra‑fast Chuck Change VC System

Ultra‑fast set‑up with high accuracy – no re‑centring required

Streamlines changeovers for high‑mix, variable-volume production and minimises machine downtime.

No re‑centring after a chuck change, so even non‑experts can perform quick, easy changeovers.

One lathe can use multiple chuck types via changeover, reducing the need to own many machines.

Ultra‑fast set‑up with high accuracy – no re‑centring required

Streamlines changeovers for high‑mix, variable-volume production and minimises machine downtime.

No re‑centring after a chuck change, so even non‑experts can perform quick, easy changeovers.

One lathe can use multiple chuck types via changeover, reducing the need to own many machines.