Kitagawa, which proposes the future of manufacturing,

shows the next-generation technologies online.

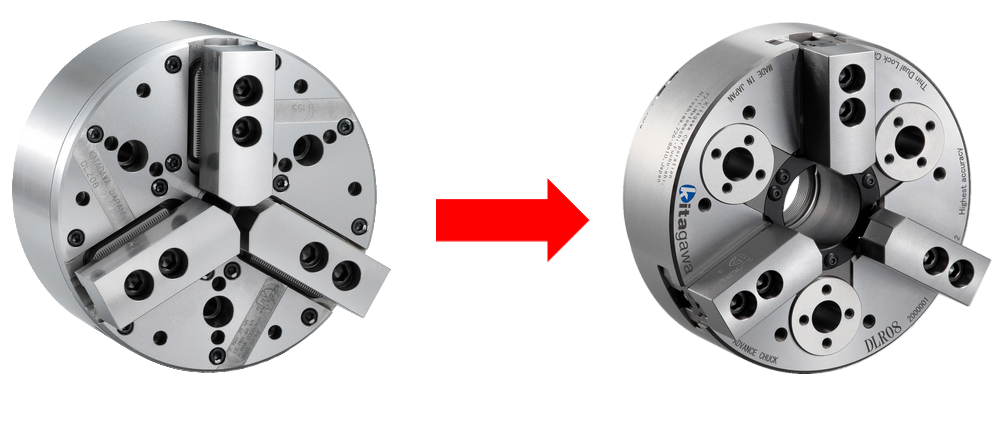

Thin dual lock chuck DLR08

The moment of inertia was reduced by 30% compared to DL208.

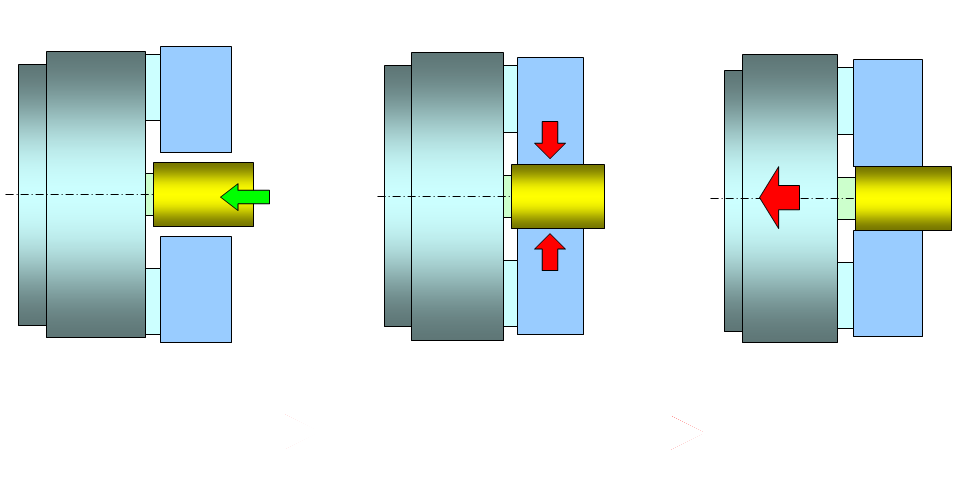

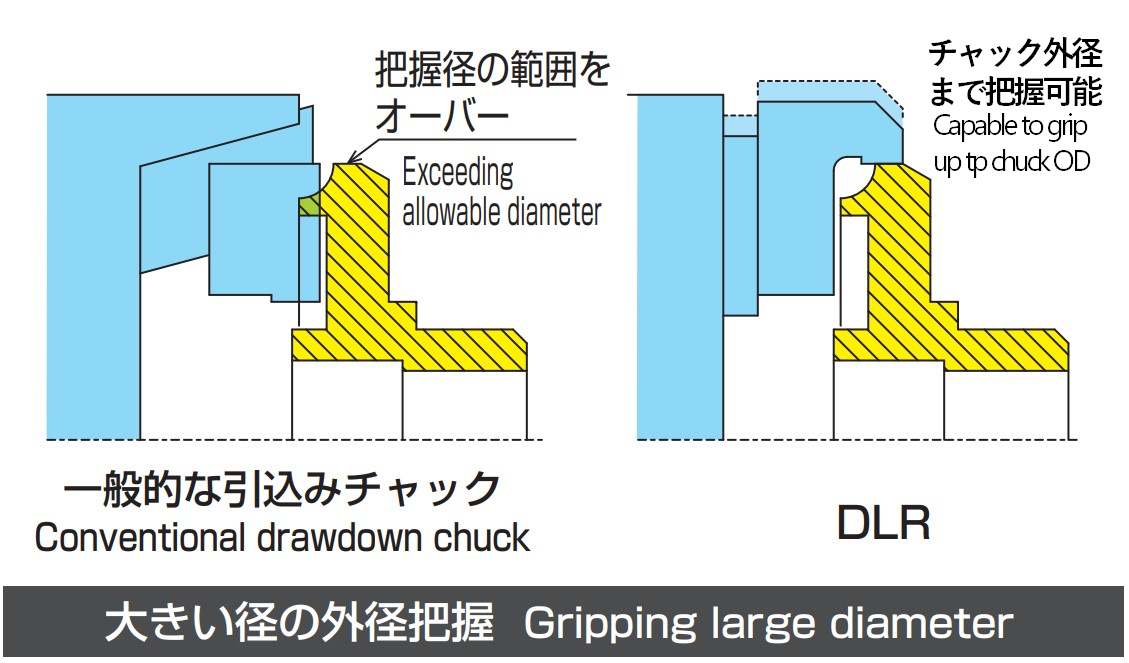

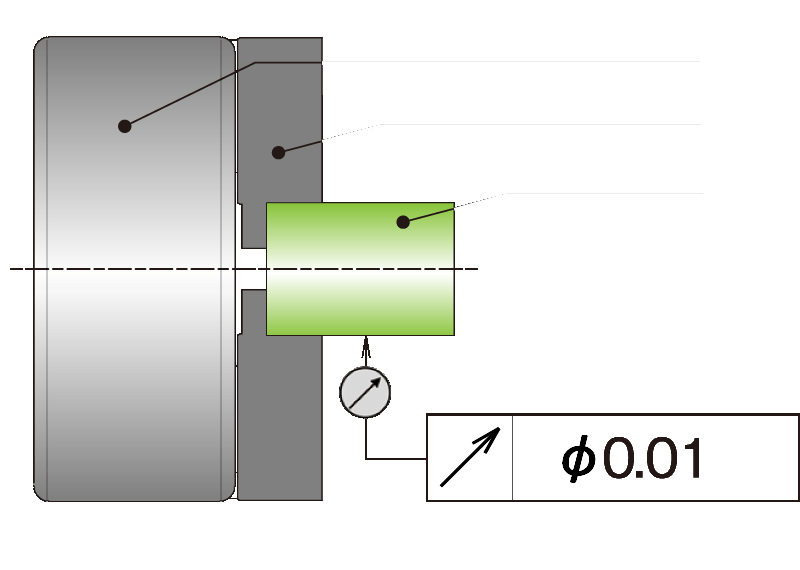

High-precision gripping

Ideal for automation and thin-wall workpiece

The moment of inertia was reduced by 30% compared to DL208.

High-precision gripping

Ideal for automation and thin-wall workpiece